Hydraulic Cylinder Maintenance and repair

We’ve been exporting Hydraulic cylinders for over 10 years,

Based on our experience, the complaint from distributors about Hydraulic cylinders are mainly two problem

Piston stuck and Oil leakage

The piston is the rod that moves up and down inside the cylinder. If the rod becomes stuck, it can’t lift and return when there is a foreign object inside or too much friction between the rod and cylinder.

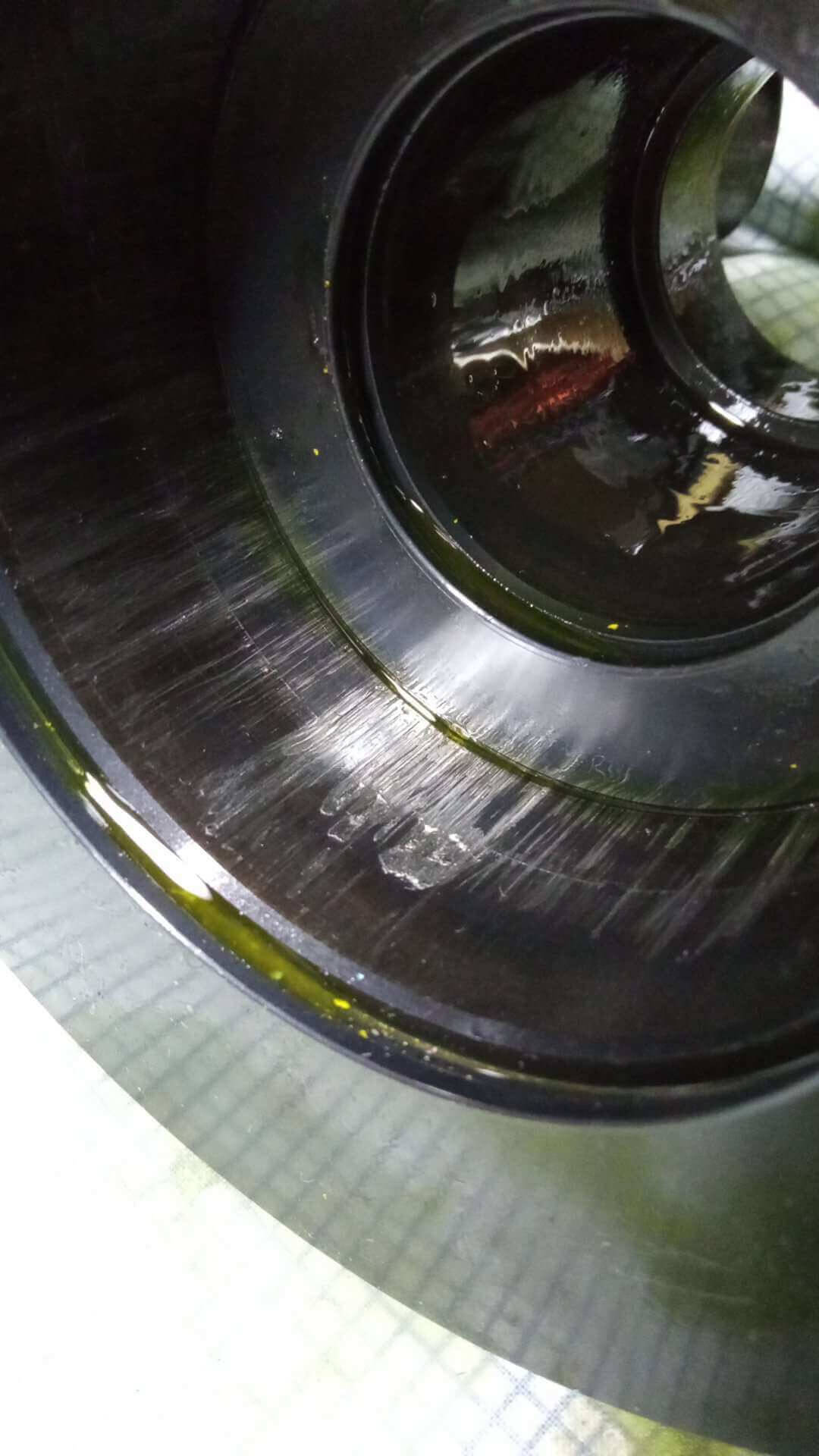

Oil leakage is when hydraulic oil goes in and leaks out from the cylinder head’s gap.

Oil leakage typically occurs due to wearing seal kits or cylinder wall scratches.

The possible causes of damage are as follows

Sideloading: Sideloading causes the piston rod not to be perpendicular to the cylinder. When the piston rod collides with the cylinder wall on a side load, it inevitably leads to permanent damage. A tilt saddle is an ideal solution for sideloading. We suggest adding a tilt saddle when you are sourcing large tonnage cylinders.

Overwork pressure: The hydraulic cylinder will be damaged if the pressure overload exceeds 70Mpa (cylinder designed working capacity). Each accessory is related to a maximum operating pressure of 70Mpa, and overpressure can deform the material.

Overloading: The load on the stroked piston becomes heavier may cause the piston rod to bend. The seal will be squeezed and deformed due to overloading. It is dangerous and may happen during the synchronous jacking lowering process if the positioning is inaccurate.

Oil contamination: Dirty stuff in the oil will wear out the seals over time, and mixed foreign objects also scratch at these parts and make them more prone to leakage.

Long-term and frequent use of the cylinder also will wear out the seals.

If a cylinder is not working, it needs urgent repair to prevent more wear and permanent damage.

Below the cylinder parts may help you to understand its structure

A Hydraulic cylinder consists of

Cylinder body

Piston (Single-acting small tonnage usually contains Spring inside)

Gland

Saddle

The seal kit (including dust seal, wear ring, Oring, PU ring, plastic gasket)

To repair the cylinder, you have to follow the below procedures

1. Dismantle the cylinder

Make sure you have ventilated the cylinder during dismantling. When the coupler is on the cylinder, you have to connect it with a matching female or female coupler, or you can move the coupler anyway to ensure that there are no vacuums inside.

2. Examine the parts and identify what might be causing the problem

Check that your piston rods and cylinder wall internals are straight and free from burrs, nicks, scars or shavings. Also, check that the seals are intact, not worn, cracked or deformed.

3. Replace the parts that are no longer working

Get the broken pieces out of the way, and give the part a thorough cleaning. Then, change the damaged accessories after you got replaced parts.

The seal kit suggested all replaced for maintenance, including dust seal, wear ring, Oring, PU ring, and plastic gasket.

4. Replace the parts that are no longer working

Get the broken pieces out of the way, and give the part a thorough cleaning. Then, change the damaged accessories after you got replaced parts.

Seal kit suggested all replaced for maintenance, including dust seal, wear ring, Oring, PU ring, plastic gasket.

5. Testing the cylinder 70Mpa

Run the cylinder at 70Mpa working pressure and check that the piston lifts smoothly. Whether there is oil leakage.