Two Common Types of 10000 psi Hydraulic Hoses

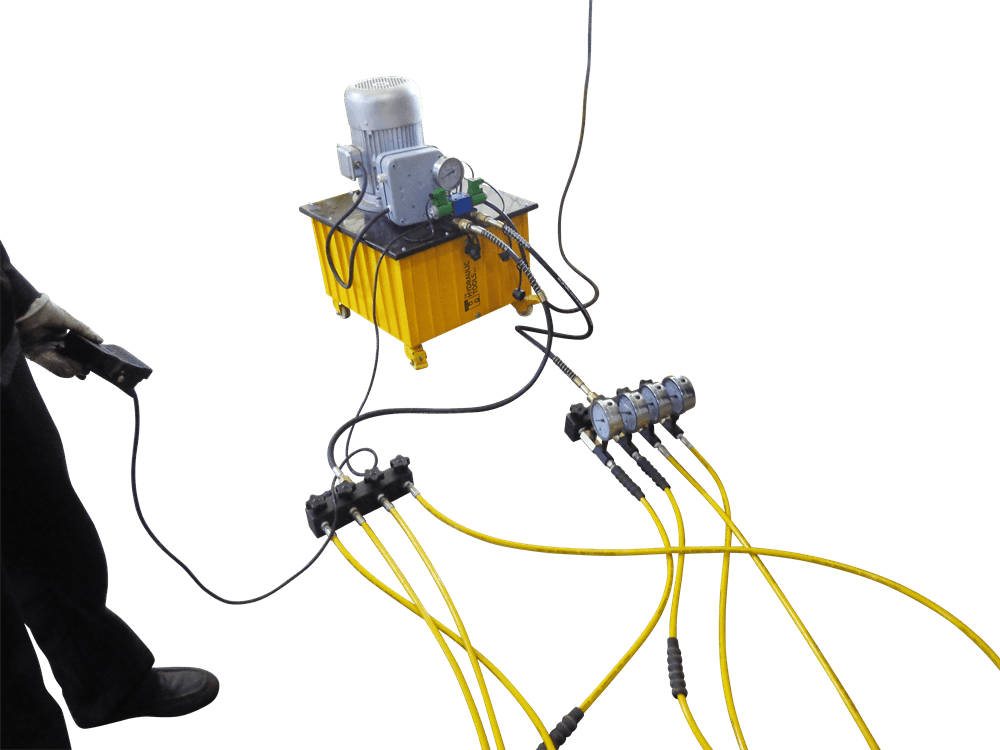

The hydraulic system mainly consists of a Hydraulic Pump, Hydraulic hose and Hydraulic cylinder. Hydraulic hose designed for hydraulic oil transmission between actuators, hydraulic components, valves and tools. The hose must fit the working condition for the hydraulic system to run with high pressure. Improper use may result in product damage or human hurt. Below are two common types of 10000 psi Hydraulic Hoses.

Thermoplastic hose

- Material Construction Tube: Polyamide (PA), Polyoxymethylene (POM) Reinforcement: Two braids of high tensile steel wire.

Cover: Polyurethane(PU)

- Working temperature: -40 °F (-40 °C) to 212 °F (100 °C)

- Media: Hydraulic Oil

- Working pressure is 10000 psi (700bar)

- Burst pressure is 2880 bar

- Hose sizes: Internal diameter: 6 mm, Hose external diameter: 14.2 mm

Rubber hose

- Material Construction

- Tube: Synthetic rubber Reinforcement: Two braids of high tensile steel wire

- Cover: Synthetic rubber

- Working temperature: -40 °F (-40 °C) to 212 °F (100 °C)

- Media: Hydraulic Oil

- Working pressure is 10000 psi (700bar)

- Burst pressure is 1120-1400 bar

- Hose sizes: Internal diameter: 6 mm, Hose external diameter: 16.5 mm

Below are Four necessary elements to check when choosing a hydraulic hose the temperature, fluid type and pressure determine to select which type of hose Users have to consider flexibility, pressure resistance, temperature resistance and Size.

Material

Different materials contribute to characteristics such as Flexibility, Radius of curvature, Chemical and corrosion resistance and extreme environmental operation and of course, the material can not react with the flowing media.

Working pressure

Every hose has its max working pressure. Overload operation shortens the hose service life and may result in hose explosion the hose working pressure has to be equal to or more significant than the hydraulic system working pressure.

Working Temperature

Exposure to continuous high temperature will cause the hose to lose flexibility and its Irreversible ageing Cover and inner tube of the hose become rigid and fragile when cooled to a sufficiently low temperature the surface may crack due to excessive exposure to extreme temperatures.

Sizes and length

The hose Inside diameter determines the flow rate. Too big ID leads to the slow transaction of the oil power too small ID would arise supper pressure inside and cause damage After outside diameter minus Inside diameter, you could get hose wall thickness and you have to choose the suitable hose length based on the distance between the Hydraulic power pack and the hydraulic matching tool on the other hand, the end pressure would become lesser if the hose is too long, the pressure will drop due to the friction between hydraulic oil and the inner hose wall.